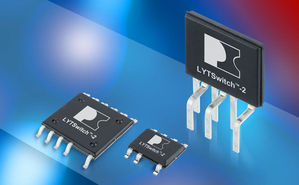

Power Integrations announced its LYTSwitch-2 family of isolated LED drivers. The new IC family, which delivers up to 12 watts of accurately controlled output power, substantially reduces component count, resulting in simpler, smaller, more reliable LED lighting designs.

|

| /news/2014/05/20/1942488980S.jpg |

LYTSwitch-2 LED-driver ICs use primary-side control, resulting in cost-effective, single-sided PCBs with low component counts. In addition, driver isolation allows the LEDs to be affixed directly to a metal heat sink, avoiding the added expense of an electrically isolating enclosure that is often required for non- isolated drivers. Accurate constant-current (CC) output tolerance across temperature (better than +/-5% at both low-line and high-line voltages) reduces the need to over-design systems in order to meet requirements such as the U.S. ENERGY STARR minimum-lumens-delivered specification. Designs

using LYTSwitch-2 ICs are also highly efficient – up to 90% in typical applications.

LYTSwitch-2 ICs protect the LED load from surges in line voltage, increasing bulb lifetime in regions where the mains voltage is subject to frequent peaks. The constant-current and constant-voltage (CC/CV) control function maintains a constant voltage on the output of the driver during no-load operation, preventing damage to the output filter or shutting down the driver when being tested or installed with no LED string connected.

LYTSwitch-2 LED-driver ICs feature over-temperature, over-current and open feedback-loop protection and are simple to design in using Power Integrations’ PI Expert design software. Devices are packaged in small, cost-efficient SO-8 packages as well as MSOP and eSIP packages for efficient thermal transfer in higher-power applications.